Barrel shaped connecting rods

Sometimes connecting rods can be barrelled shape. They can also be made so they are most appropriately called fish bellied. This can be seen as being a barrel shape that has been cut on both sides so it is flat.

Making a shallow curved surface that lies across the bed of the lathe has been covered elsewhere. One of the ways of doing this was with a linkage to control the movement of the cross slide. But here the curve lies along the bed of the lathe. This leaves only one practical way. This is to cut the curve as a series of straight segments.

In the following example the length of the curve is about 120mm long. This is cut with a middle segment of 10mm which is parallel. Then on either side a series of cuts are made. The first starts at the left of the middle segment and is done at an angle of 1º. This cut goes right to the end on the left. The second cut start another 10mm to the left and is done with an angle of 2º.

When all of the cuts have been made it is only just possible to feel the points where the angle changes.

The surface is then cleaned up with abrasive tape. This only took a few minutes produce a really good surface which feels perfectly smooth andvround in both dimensions.

The radius of the curve is probably too great to look appropriate on a coupling rod but a greater curvature would not have shown up in a photo so well.

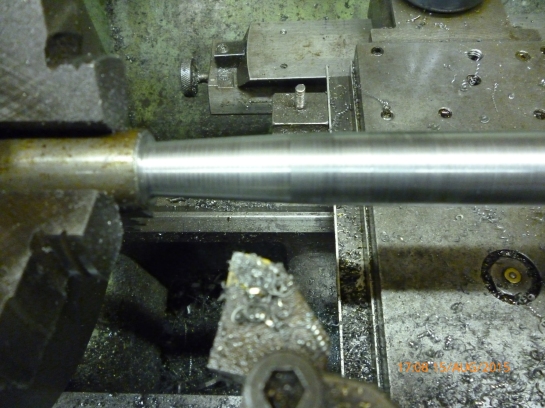

fig starting workpiece – surface just cleaned up

fig first cut completed

fig second or is it third cut

fig last cut and polished